Based on the philosophy and policies of quality assurance, Nissui and the Group companies are engaged in all manner of initiatives to deliver tasty, safe and secure products. Our commitment is indispensable in providing “quality” that satisfies our customers.

(1) Employee Training

Nissui conducts various types of education and training so that all employees, as members of a food manufacturer, become aware of their roles to be fulfilled toward quality and become capable of acting based on a higher level of knowledge.

The Quality Assurance Department conducts periodic training so that employees who handle products can accurately acquire the required knowledge. The content of the training is reviewed each year and efforts are made to always share the latest information. Since fiscal 2020, courses in streaming video format and online training seminars have been introduced. In video-streamed courses, participants watch a video and check their level of understanding by working on assignments (mini-exams) on an individual basis. While taking a course, participants are provided with support from their boss and senior colleagues to help them further improve their understanding.

| Name of the training | Target | Details of the training | Training method and duration | Number of participants | ||

|---|---|---|---|---|---|---|

| FY2021 | FY2022 | FY2023 | ||||

| Online HACCP Course | Operational managers | Gaining basic knowledge related to HACCP and utilizing HACCP at production sites

|

The course is divided into three segments, in which a total of 20 videos (approx. 10 to 20 minutes per video) are streamed. Participants are required to watch the videos and work on assignments on an individual basis to complete the course in a total of five months. |

68 | 66 | 92 |

| Course for Quality Trainers at Production Plants | Plant managers, persons responsible for quality control, site supervisors and other persons in a position to promote quality training at plants (i.e., those in a position to train participants in the “Online HACCP Course”) | Learning the risk management approach at production sites, watching lecture videos on quality training targeting operational managers and putting them into practice | The course is divided into two segments, in which a total of 8 videos (approx. 10 to 25 minutes per video) are streamed. Participants are required to watch the videos and work on assignments on an individual basis to complete the course in a total of two months. |

83 | - | 71 |

| Basic Training on Quality Control | Plant personnel (Primarily those within their first ten years of employment) |

|

Online lectures and tests. Completed in one day. | - | - | 111 |

| Quality Seminar for Sales Staff | All sales business department staff |

|

Materials are distributed to participants, and their level of understanding is checked through a test conducted on the Web (i.e., e-learning system). The seminar is divided into four segments and to be completed in a total of four months. | - | - | 69 |

| Training on Certificates of Guarantee for Raw Material Specifications | New personnel in charge of departments that obtain Certificates of Guarantee for Raw Material Specifications, such as product development departments | Understanding of structure, precautions, and case studies of problems related to Certificates of Guarantee for Raw Material Specifications | Face-to-face & online information sessions | 54 | 161 | 89 |

| Training on Standards Related to Raw Materials and Labeling | Persons in charge of development/quality control/purchasing at development departments/raw materials departments/production promotion departments and production plants, etc. | Understanding raw material product certificates and related quality assurance standards | Explanation of content and verification of understanding through a web test (e-learning system) | 68 | 311 | 329 |

| Training on Raw Materials/Labeling Topics | Those from product development, production, sales, and other related departments |

|

Explanation of content and verification of understanding through a web test (e-learning system) | - | 229 | 458 |

Plant workers who actually come into contact with the products and support manufacturing receive a training that is more in line with the production site. Even new employees on their first day of work have the duty to maintain quality. There is no room for compromise. Such a production site is created by the concerted efforts of all employees.

This basic seminar is attended by all employees assigned to work at the plant. They learn the basics which are required of employees who are responsible for maintaining quality including appropriate clothing, rules for entering the plant, hand-washing, etc., not to mention labor safety.

The plants operate every day and produce numerous products. Employees at the sites, when they come to work, always receive communications on quality-related topics and precautions from their site leader. Nissui ensures that such matters are communicated to all employees at the production sites which operate every day.

(2) Quality Control

The factory sites receive raw materials and manufacture products. The quality of the products to be delivered to customers are created at strictly-controlled production sites.

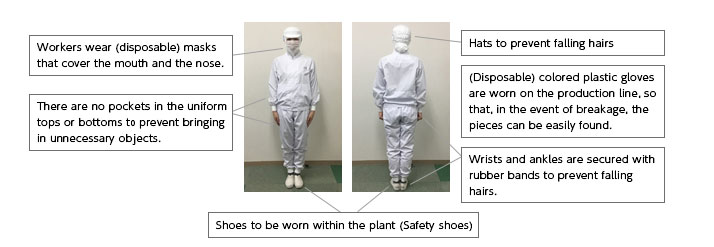

All employees change into the prescribed work uniforms before entering the production sites. These work uniforms also play a part in maintaining quality.

There are rules that must be followed when entering the plant. These rules must be followed even when the worker is in a hurry.

The health of the worker is checked every day. Does the worker have a fever? Does the worker have diarrhea? Is there a cut on the hand? And so on. The worker must check multiple items before entering. The plant cannot have product contamination by even one worker who is ill. To maintain one’s health every day is also another important mission of a worker who works at the plant.

Hairs stuck to the work uniform are removed using a sticky roller.

There are also rules for using the roller. The rules are illustrated so that foreign workers who do not speak Japanese will also understand. Additionally, each worker checks the mirror to confirm that the uniform is not disheveled and that no hairs are sticking out of the hat.

There are also rules for washing their hands, which is important for workers handling food. Workers wash their hands according to a timer which has been set to a designated time. These rules are also illustrated with photos so that they are easily understood.

Workers basically enter the plant without bringing anything in. However, there are certain things which are required in the course of operations, such as when records or photos must be taken, that are allowed on site. All objects must be made of metal to prevent fragments from entering the product, in the unlikely event that the object breaks.

(Note): As all products go through a metal detector in the final process, any metal contaminant will be found.

Various checks are carried out in the plant. Several dozen items are checked in the process of making a single product, including the type of raw materials, the weight, the composition, the order, the time, the heating temperature, the cooling temperature, the print on the wrapping, the condition of the machine, etc. All of these items are double-checked, including person-to-person checking and machine-to-person checking. Furthermore, subsequent checks of the records are made by the administrator.

Errors will inevitably occur if checks are conducted by a single person. Machinery may also malfunction if we depend solely on machines. We have a system in place in which checks are always conducted by several different eyes at every stage, in the case of emergencies.

As many employees work in vast spaces within the plant, early detection of “anything out of the ordinary” is essential. To this end, cameras have been set within the plant to guard the employees so they can work properly.

Furthermore, storage areas for detergents used in washing and drugs used in testing are strictly kept under lock and key and only a few people are allowed the use of the key. In such cases, also, records of opening and closing the locks are taken.

Moreover, a number of production plants have vein authentication and fingerprint authentication management systems to monitor who came into the plant and at what time. More of the domestic plants of the Nissui Group will adopt this system down the road.

(3) Inspections

Nissui only uses raw materials that have been confirmed for safety in manufacturing its products. It also conducts inspections at each stage from raw materials to the finished product to confirm that it conforms to the standards. These inspections encompass a wide variety of items and inspection methods, and require specialized knowledge and technology. Therefore, in order that inspectors are always able to carry out proper inspections, Nissui promotes “Excellent Lab” program, a system that allows inspectors to acquire the necessary knowledge and inspection skills.

The Nissui Group production plants nationwide all have inspection offices. Excellent Lab program is carried out mainly by the Food Safety Research Department in order to enhance the reliability of the inspection offices. Through standardized inspection manuals, the setting of facility standards, skill certification of the inspectors, precision control tests, and level-specific seminars, we are raising the level of the entire Excellent Lab. Excellent Lab program has also been introduced at certain overseas plants including China, as well as Japan.

Manual content is reviewed on a regular basis, and the latest version is always available for reference at each inspection office. To ensure that all inspection offices maintain the same level of accuracy in their inspections, a dedicated medium for the Excellent Lab is used and reagents are specified. This medium is packaged in single-use packets eliminating the need for measuring as well as preventing errors on the part of inspectors and saving time.

![[Cover] Excellent Lab Inspection Manual](/assets/img/site/98/98_86_img-01.svg)

To ensure that inspections are carried out by inspectors with a certain level of knowledge and skills, inspectors are registered and the skills of each inspector undergo certification. When employees are first assigned to the inspection offices, they receive instruction under the inspection office’s OJT program. After the employee becomes capable of carrying out most inspections on his or her own, he or she is certified as an A-level Inspector. Proficient inspectors who have acquired a certain level of experience are certified as M-level Inspectors and inspectors capable of carrying out even higher-level tests are certified as E-level Inspectors. Inspectors must undergo written and skill tests to be promoted to the next level of inspector. In fiscal 2023, M-level and E-level certification workshops were held, and a number of inspectors were promoted.

![[Photo] Certification of the Inspectors’ Skills](/assets/img/site/98/98_86_img-02.webp)

| Definition | FY2021 | FY2022 | FY2023 | |

|---|---|---|---|---|

| A-level Inspector | Capable of carrying out designated tests | 36 | 34 | 45 |

| M-level Inspector | Capable of providing instructions to inspectors aiming to become A-level Inspectors | 59 | 60 | 53 |

| E-level Inspector | Capable of carrying out tests of a high degree of difficulty, and is proficient in all required tests | 22 | 25 | 30 |

The Excellent Lab emphasizes communications between the inspectors through various exchange events and the exchange of information. Inspectors periodically gather at venues around the nation and hold Excellent Lab Promotion Meetings. In fiscal 2023, 12 sessions were held both in-person and online, with the participation of 97 inspectors. Efforts are being made to maintain and improve the level of inspections by implementing activities such as aligning perspectives on inspection methods and assessment criteria, sharing information on new inspection techniques and promoting communication between inspectors.

![[Photo] Communications Between Inspectors](/assets/img/site/98/98_86_img-03.webp)

In order to confirm the testing precision of the inspection offices, precision control tests are conducted once a year. Specimens distributed by the Food Safety Research Department are individually tested by each inspector, and the results are statistically analyzed by the Food Safety Research Department and communicated back to the inspectors. These results are used to verify the continuity of skills in inspection offices and to improve inspection procedures.

![[Photo] Precision Control Tests](/assets/img/site/98/98_86_img-04.webp)

The overseas plants that manufacture the products imported into Japan are also training their inspection offices using similar systems. In China, Qingdao Nissui Food Research and Development Co., Ltd. and in Thailand, the Quality Control Section Thailand of the Quality Assurance Department, are leading efforts to provide testing instructions to local plants.

(4) Communication

We stress the importance of listening to the candid comments of the customers, and also believe that providing accurate information to customers is essential. We aim to create superior products based on the voices of the customers in order to enhance customer satisfaction.

The Nissui Customer Services Center is where we can speak directly with the customers who have purchased our products. Currently, we receive comments by phone and via email. We not only receive complaints but also questions, confirmations and commendations. Whatever its content, each comment is a valuable piece of information for us.

Nissui Customer Services Center (Phone number): 0120-837-241

The “Customer Satisfaction Improvement Subcommittee” is held six times a year to share the comments provided by the customers. There are many cases in which product specifications were changed as a result of the discussions by the subcommittee. We value the perspectives that are unique to the general customer and utilize such perspectives in creating superior products.