Global seafood consumption has been increasing and demand is expected to continue growing in the future. In order to deliver safe, secure and delicious fish to its customers, the Nissui Group has been focusing on its aquaculture business both in and outside Japan. Outside of Japan, the Group is engaged in the aquaculture of salmon and trout, while in Japan the Group operates the aquaculture businesses of yellowtail, greater amberjack, tuna, coho salmon and mackerel, among others.

Furthermore, the Oita Marine Biological Technology Center of the Central Research Laboratory is conducting research and development specializing in aquaculture that translates into the sustainability of marine resources.

The Center contributes to the Nissui Group’s aquaculture business by conducting research on problems that threaten the stable growth of fish.

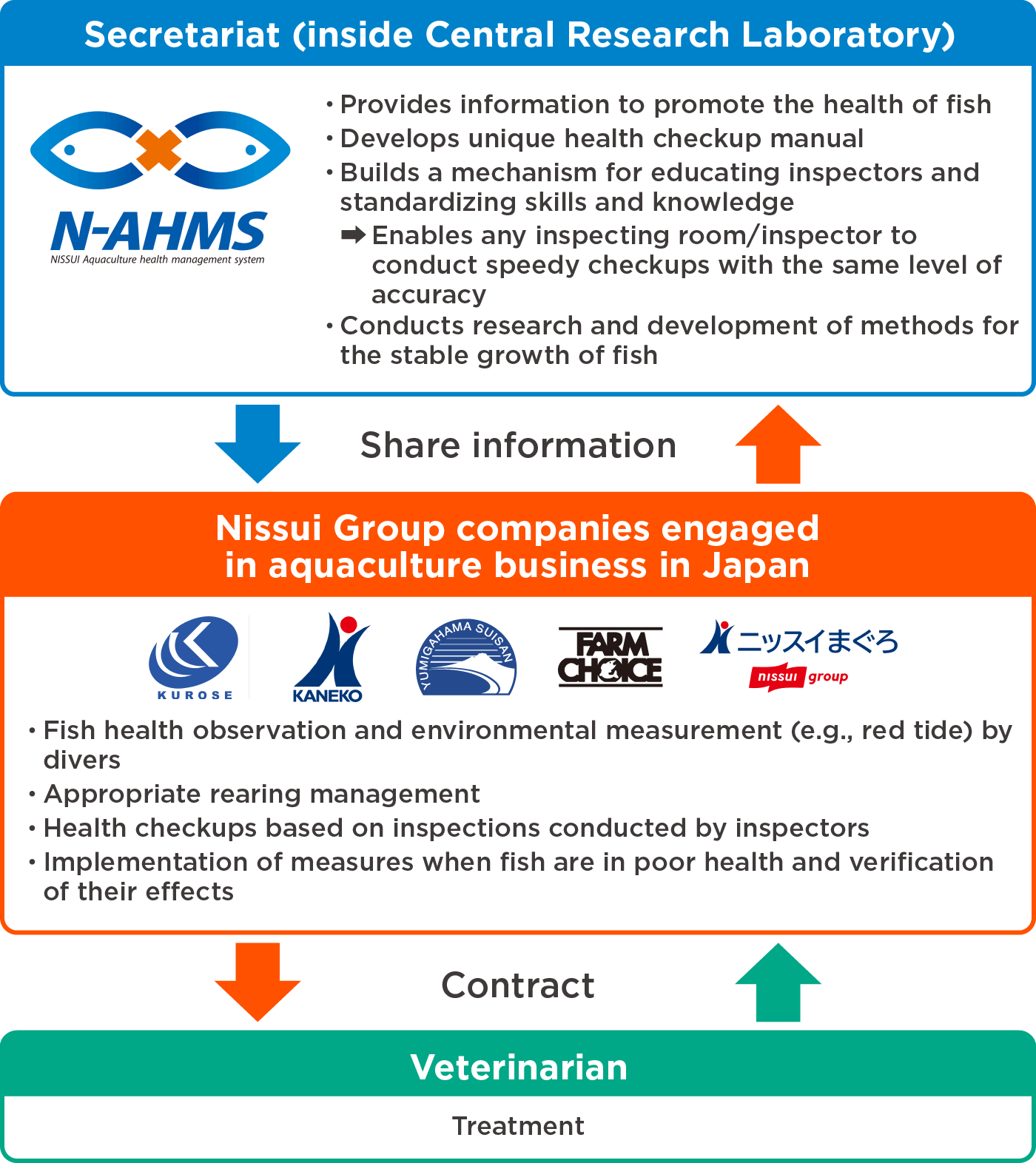

The Nissui Group has built a system to manage the health of fish in Japan named N-AHMS (NISSUI Aquaculture health management system). Under N-AHMS, standardization of inspection quality is pursued through the establishment of an in-house certification scheme for grade-A inspectors in charge of checking the health of fish, their instructors, etc. aimed at improving the accuracy and reliability of health checkups of fish.

| FY2021 | FY2022 | FY2023 | |

|---|---|---|---|

| Instructors (Note 1) | 11 | 1 | 0 |

| Grade-A inspectors (Note 2) | 25 | 8 | 11 |

| Sub-grade A inspectors (Note 3) | - | 3 | 0 |

As of the end of March each year

Scope: All consolidated companies of the Nissui Group in Japan (aquaculture companies only)

(Note 1) Instructors: Capable of training apprentice inspectors into grade-A inspectors.

(Note 2) Grade-A inspectors: Capable of arriving at the correct outcome by conducting health checkups of fish reared in fishing grounds.

(Note 3) Sub-grade A inspectors: Capable of arriving at the correct outcome by conducting health checkups of fish reared in fishing grounds (limited to observations and microscopic examinations).

The Nissui Group has entered into a contract with veterinarians, under which they provide treatment based on the results of health checkups performed by inspectors, manage the use of fisheries medicine and give guidance on epidemic prevention and health management.

The Nissui Group, which relies on the bounty of the sea, recognizes the importance of animal welfare in its aquaculture operations. We support the “Five Freedoms (Note)” for animal welfare established by the World Organisation for Animal Health (WOAH) and are committed to continually improving the welfare of farmed fish.

(Note)The Five Freedoms: Freedom from hunger, thirst and malnutrition; Freedom from fear and distress; Freedom from physical and thermal discomfort; Freedom from pain, injury and disease; and, Freedom to express normal patterns of behavior.

The Nissui Group Aquaculture Business

For each fishing ground, we select locations capable of maintaining comfortable water temperatures and oxygen levels suitable for each species. Additionally, we manage the density within the pens to ensure the fish can grow healthily and exhibit their natural behaviors. When national or regulatory standards for aquaculture density exist, we comply with these guidelines in our operations.

We do not use antimicrobials for disease prevention or growth promotion in fish. Additionally, all decisions regarding the type and timing of antimicrobial use are made under the supervision of a veterinarian or specialist.

We conduct daily or periodic monitoring of the aquaculture environment, as well as the physical condition and health of farmed fish. If the monitoring indicates a need for improvement, we promptly implement corrective measures.

We select methods that minimize stress to the farmed fish and ensure that the slaughter process is completed quickly. In addition, we strive to stun before slaughter using methods that meet welfare standards for all farmed fish. From a welfare perspective, we continually seek better stunning techniques and procedures and work to improve our operations.

Enactment Date: February 19, 2024

One of the diseases that pose a problem in the ocean farming of yellowtail, etc. is skin parasites, namely, capsalids, which parasitize the surface of the body of fish. Jointly with a veterinary pharmaceutical company, the Oita Marine Biological Technology Center has developed and put to practical use a method of removing skin parasites (capsalids) by bathing fish in a low-concentration hydrogen peroxide solution (1/3 of the concentration in normal use) in consideration of the safety of fish as well as the environment.

The spread of sea lice is a major challenge for the vast majority of businesses in the salmon farming industry worldwide. In Chile, where Nissui Group company Salmones Antártica S.A. (“SA”) runs an aquaculture business, a nationwide monitoring and control program is implemented by the National Fisheries and Aquaculture Service (Sernapesca) to prevent the spread of sea lice infections through farming sites.

SA participates in the government’s control program and takes countermeasures against sea lice. In addition, SA is working on the following strategies to further improve the countermeasures against sea lice going forward:

In its aquaculture operations, the Nissui Group prioritizes minimizing fish stress by using efficient and humane slaughter methods to ensure the welfare of all fish species. For 100% of the total harvest volume (metric tons), we use short-duration stunning techniques that minimize stress. In addition, for 98% of our harvest volume (metric tons), we either currently use pre-slaughter stunning (Note) or are actively exploring process improvements to encourage its use. In salmon farming, we consistently perform pre-slaughter stunning on the entire harvest volume (metric tons). The stunning methods used by the Nissui Group primarily incorporate the use of electrical stunning.

(Note) Pre-slaughter stunning: The process of rendering fish unconscious and numbing their senses prior to slaughter to prevent them from getting stressed.

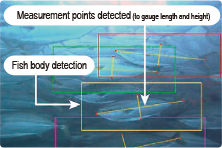

In collaboration with electrical equipment manufacturers, the Nissui Group has co-developed a solution that automates the measurement of the size of farmed fish, such as of body length, by leveraging the advanced AI and IoT technologies these companies offer. This solution is currently being used in aquaculture settings. In aquaculture, there is a need for such solutions to constantly manage the growth status of the fish. This solution alleviates the risk of stress or disease that comes from people physically handling fish. It also reduces labor and inconvenience, and improves measurement accuracy, thereby boosting productivity. The Nissui Group will continue to deliver safe, secure and delicious farmed fish by expanding the scope of AI and IoT utilization.

| Number of companies | |

|---|---|

| Implementation status of fish measurement system | 5/5 companies |

As of March 2024

Scope: All consolidated companies of the Nissui Group in Japan (aquaculture companies only)

Image Showing AI Detection of Yellowtail

When using antimicrobials, an appropriate medicinal product is administered under the supervision of a veterinarian/specialist after the diagnosis of the fish disease.

As a member of the Seafood Business for Ocean Stewardship (SeaBOS; an initiative aiming at sustainable fishery business), the Nissui Group is working on reducing the use of antimicrobials in aquaculture.

| Fish species | Region/Country | Antimicrobials (g)/Harvest volume (t) | |||

|---|---|---|---|---|---|

| 2020 | 2021 | 2022 | 2023 | ||

| Coho salmon | Japan | 0 | 0 | 0 | 0 |

| Chile | 53 | 8 | 23 | 20 | |

| Total | 53 | 8 | 23 | 20 | |

| Trout | Chile | 565 | 306 | 336 | 369 |

| Total | 565 | 306 | 336 | 369 | |

| Aggregate total | 439 | 229 | 277 | 308 | |

Scope: Farming of coho salmon and trout by Nissui Group’s consolidated companies in and outside Japan (accounting for % 71of harvest from all aquaculture operations in terms of weight (2023))

The Nissui Group aims to reduce the escape of fish to zero with the understanding that fish escaping from farming sites has the risk of affecting the ecosystem. For this purpose, the Nissui Group will engage in the following initiatives.

| Region/ Country |

Fish species | 2021 | 2022 | 2023 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of escape incidents | Number of fish | Number of escape incidents | Number of fish | Cause | Recurrence Prevention Measure |

Number of escape incidents | Number of fish | Cause | Recurrence Prevention Measure |

||

| Japan | Yellowtail | 1 | 198 | 4 | 39 | Operational error |

Improve operational environment during medicinal bath treatments for farmed fish | 3 | 11,108 | Operational error |

|

| Greater amberjack | 1 | 10 | 0 | 0 | - | - | 0 | 0 | - | - | |

| Bluefin tuna | 0 | 0 | 1 | 740 | Natural disaster |

Introduction of tanks with high shape retention functionality/tanks with ultra-rigid netting | 0 | 0 | - | - | |

| Coho salmon | 1 | 28,628 | 0 | 0 | - | - | 0 | 0 | - | - | |

| Chile | Trout | 0 | 0 | 0 | 0 | - | - | 0 | 0 | - | - |

| Total | 3 | 28,836 | 6 | 779 | - | - | 3 | 11,108 | - | - | |

Scope: All consolidated companies of the Nissui Group in Japan and overseas (aquaculture companies only) and domestic aquaculture-related facilities.

| Region/Country | No. of implementing companies | Training content example | |

|---|---|---|---|

| FY2022 | FY2023 | ||

| Japan | 6/6 companies | 3/5 companies | Workshop: “Efforts to Prevent the Escape of Farmed Fish” |

| Chile | 1/1 company | 1/1 company | |

Scope: All consolidated companies of the Nissui Group in Japan (aquaculture companies only)

Ordinary feeding methods in aquaculture may cause deterioration in water quality at farming sites and their surrounding areas due to leftover feed. To address this, the Nissui Group is promoting the development of aquaculture technologies that alleviate the impact on the marine environment and minimize the effect on marine ecosystems, such as formula feed “EP feed,” which is highly digestible and not easily dissipated into the sea during feeding, and automatic feeding control system “Aqualingual®” which provides the appropriate amount of feed according to the appetite of the fish.

![[Photo] EP feed](/assets/img/site/144/144_409_img-01.jpg)

EP feed

![[Photo] Aqualingual® Feeding System in Otsuchi-cho, Iwate Prefecture](/assets/img/site/144/144_409_img-02.jpg)

Aqualingual® Feeding System in Otsuchi-cho, Iwate Prefecture

| Fish species | Region/Country | Initiatives |

|---|---|---|

| Vannamei (whiteleg shrimp) | Japan (Kagoshima prefecture) | Following a feasibility study of land-based aquaculture using the 'closed biofloc method,' the project has been commercialized from April 2023. This reduces the amount of water used to the bare minimum required for raising shrimp and uses aggregates of microorganisms (i.e., bioflocs) in the rearing tank for water treatment. |

| Chub mackerel | Japan (Tottori prefecture) | The Nissui Group and Hitachi Zosen Corporation are engaged in the joint development of land-based recirculating aquaculture technology for chub mackerel. The environment is optimally controlled in terms of water temperature and water quality with the use of underground seawater and a recirculating water treatment system. As it does not use seawater sourced from the open sea, it reduces the risks of parasites such as anisakis. |

| Atlantic salmon | Denmark | In April 2020, Nippon Suisan (Europe) B.V., together with Marubeni Corporation, acquired a capital stake in Danish Salmon A/S, a company engaged in the business of farming salmon using recirculating aquaculture systems (“RAS”) in Denmark. The expansion work completed in 2023. It plans to increase its production scale from the current harvest volume of 1,000 tons to 2,700 tons. |